Why Its

Necessary for

Necessary for

Home Owners/DIY ers

Normal sand does not ensure uniform particle size distribution, which can affect the quality of plaster.

Traditional Sand used in plastering typically has particle sizes less than 2.36 mm which are not proportionate, leading to Inconsistent Quality in final plaster mix.

Xpress Plast uses precisely Graded Sand.

This ensures uniform particle size distribution, resulting in high-quality plaster. DMM Plant Precisely controls particle size distribution.

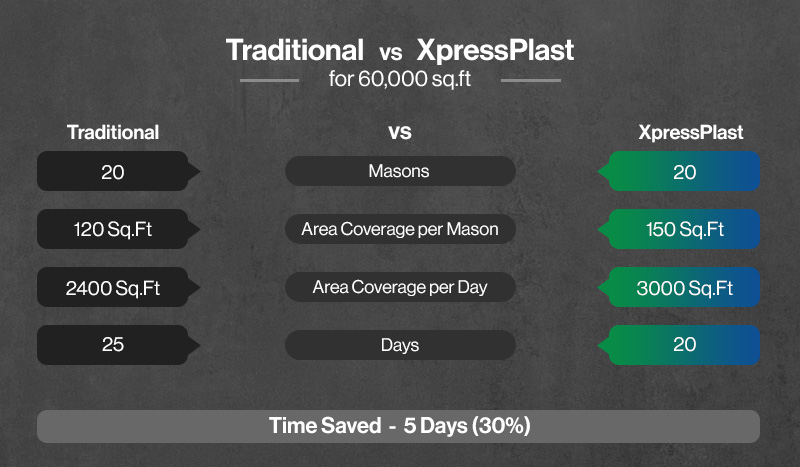

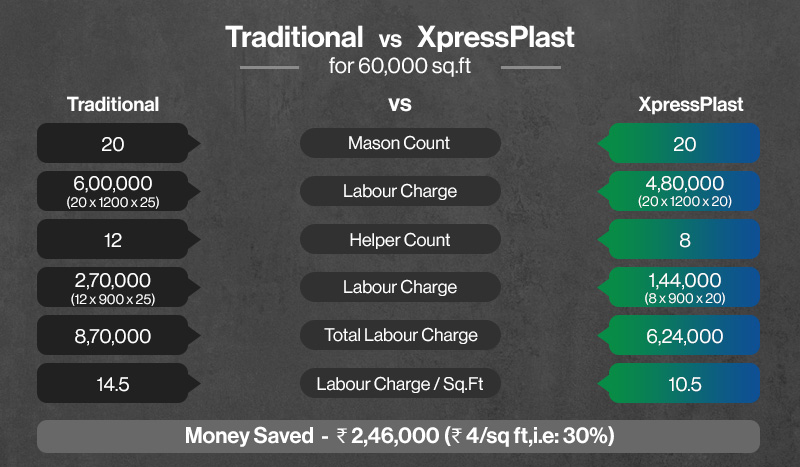

Xpress Plast saves costs by streamlining operations and reducing the need for unskilled labor, while still prioritizing skilled craftsmanship and top-notch quality.

Reduced Rebound Wastage: Xpress Plast minimizes wastage by polymer formulation, cutting down on rebound significantly.

Efficient Mixing Process: Xpress Plast eliminates the need to shift materials to the mixing area, saving time and enhancing productivity on site by instant mix feature.

Reduced Need for Unskilled Labor: Xpress Plast cuts costs by minimizing reliance on unskilled labor and streamlining operations, including efficient material handling processes.

Using Xpress Plast eliminates the need for grout on ceilings, reducing overall costs effectively.

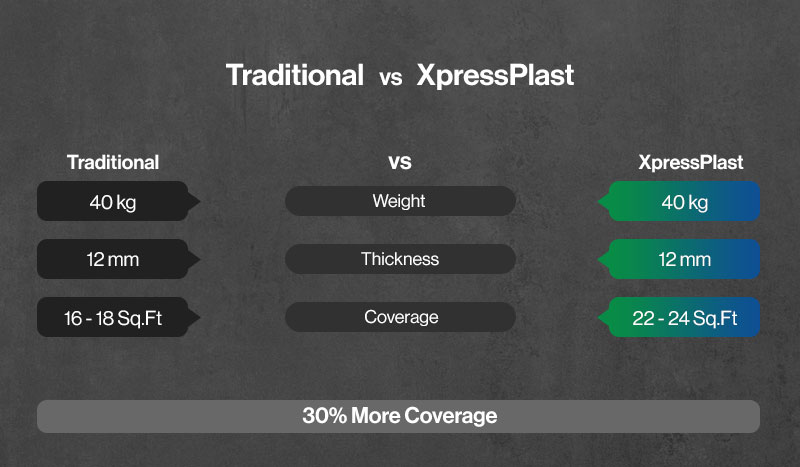

The enhanced coverage achieved by graded sand and fibres formulation. Graded sand ensures uniform particle size, which contributes to smoother finish and better surface coverage. The addition of fibres enhances the strength and cohesion of the plaster mix, reducing shrinkage and cracks while providing a more durable finish. This optimized formulation allows for more efficient usage of the plaster mix, covering larger areas with less material, thereby improving overall project efficiency and reducing costs.